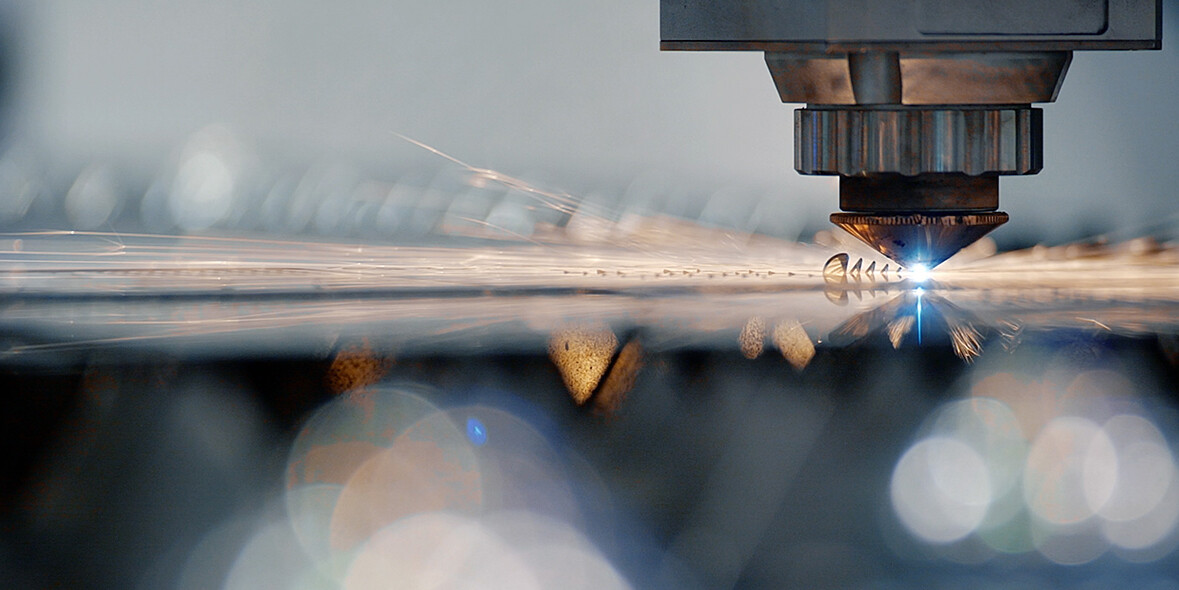

Laser Cutting

Cutting gas regulation is one of the key factors for outstanding cutting results and machine productivity. We at HOERBIGER can help you optimize your entire gas supply and offer you sophisticated cutting gas solutions in order to achieve the best cutting performance with your machine.

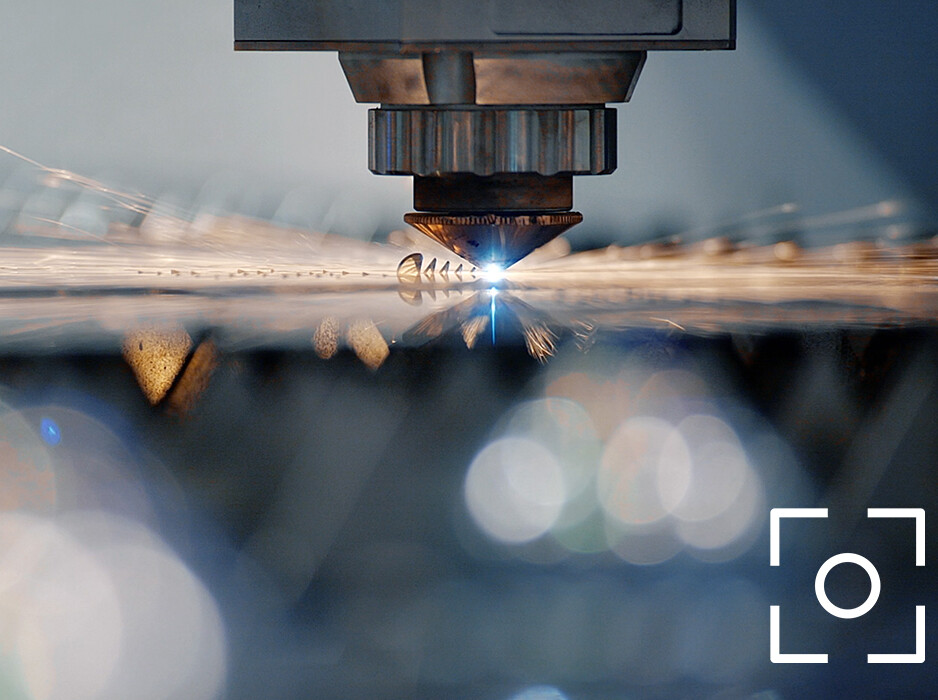

Adjust the focus in laser cutting heads

Application

- Variable adjustment of the laser power in the cut

- Keep the speed and dynamic also in curves high

- Super lightweight solution to get higher speed in your X-, Y- and Z-axle

- Precise and fast adjustment of the focus during the cut

Related HOERBIGER products:

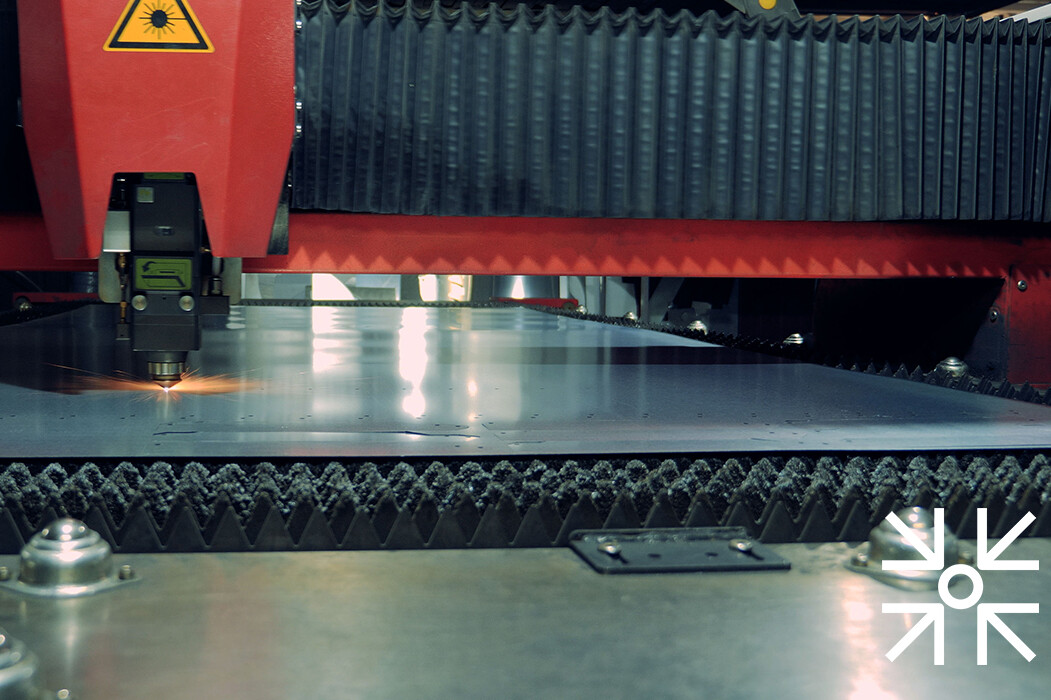

Highest pressure control without Stress

Application

- LasGAR is used to control the gas pressure in the Laser Cutting machine

- LasGAR can switch between up to 4 different applied gases

- The maximum regulated gas flow provided through the LasGAR is reducing the burr and increases the cutting speed

- P9 – Piezo pilot valve enables the LasGAR extremely high number of switches over lifetime

Related HOERBIGER products:

Join the evolution with LasGAM!

Application

- Safe costs and energy with our LasGAM because you are able to reduce the gas consumption up to 55 %

- With the LasGAM gas mixing unit it is possible to add a definable proportion of oxygen to the cutting gas nitrogen and thus reduce the “rough” cutting edge and increase cutting speed!

- Reduce the oxide layer compared to pure oxygen cutting

- You could weld and coat directly after the cut

Related HOERBIGER products:

How can we help you?

Let us know if you need assistance or have questions – one of our compression representatives will contact you as soon as possible.

Don’t miss out on the latest news!

Sign up below to receive the latest news and updates from HOERBIGER about our compression products and services.